Home / Blog / Vertical Farming 2021 (The MEGA Report)

We've all heard about "vertical farming".

But you're probably wondering:

"What is vertical farming, and how does it work?"

Or Maybe:

"What are some vertical farming advantages?"

Or Maybe Even:

"Can I do it on a small scale myself?"

Short on time?

Well:

All of these answers and more are discussed in this article.

So here's the goal:

At the end of this article, you should have enough knowledge to start planning your own vertical farm.

So let's get started...

1. What is Vertical Farming? (A Definition & Comparison vs Traditional Farming)

2. What is the History/Timeline of Vertical Farming? (Starting with Dickson Despommier)

3. What are the Different Vertical Farming Systems, Methods, and Designs? (Vertical Farm Buildings & Architecture)

4. Pros and Cons of Vertical Farming

5. Vertical Farming Disadvantages (Why Vertical Farms Fail)

6. Vertical Farming Companies Examples (Plenty, Square Roots, Aerofarms, etc), Investing and Stock Opportunities

7. How Vertical Farming Works (With a Diagram)

8. How To Start Vertical Farming (Starting Your Vertical Farming Business Plan)

9. Vertical Farming at Home on a Small Scale / DIY Vertical Farming Towers

10. Vertical Farming Costs and Economics

11. Vertical Farming Companies In the USA (New York, Chicago, Philadelphia, Boston, Seattle, etc)

12. Vertical Farming Companies Across the World (Singapore, India, Japan, etc.)

13. Vertical Farming Advantages (Benefits of Vertical Farming)

14. Vertical Farming vs Hydroponics (Vertical Hydroponic Farming)

15. Vertical Farming Books

16. Vertical Farming Jobs

17. Vertical Ocean Farming

18. Vertical Farming Equipment, Supplies, and Systems for Sale

19. What is the Association of Vertical Farming (AVF)?

20. Vertical Farming vs Aquaponics (Vertical Aquaponic Farming)

21. Vertical Farming vs Aeroponics (Vertical Aeroponic Farming)

22. Grow lights used with Vertical Farms (LED Vertical Farming)

23. Greenhouse Vertical Farming

24. Detailed Vertical Farm Diagrams and Components (PDFs)

25. Vertical Farming Crops (Tomatoes, Lettuce, Cannabis etc.)

Conclusion: Vertical Farming Facts & The Future of Vertical Farming

Here's the deal:

Most people think vertical farming is the process of growing vertically in "stacks" into the air.

But here's the kicker:

Vertical farming is the practice of growing crops in vertically stacked layers. It often incorporates controlled-environment agriculture, which aims to optimize plant growth, and soilless farming techniques such as hydroponics, aquaponics, and aeroponics.

Although many vertical farms are built in large stacks of layers, the defining trait of a vertical farm is that the "plane" of growing is vertical, not horizontal (like traditional farming).

So in reality:

Vertical farming can be in just in one layer (But usually it's more).

Now, keep in mind:

Vertical farming often but not always uses technology to aid the growing process, for example common elements include:

- humidity control

- temperature control

- artificial lighting (mixes of artificial and natural light can be used)

- control / monitoring of nutrients and fertilizer

The timeline of vertical farming spans mostly the past 30 years.

The modern concept "vertical farming" was actually popularized in the 1990's (over 25 years ago!) by Dickson Despommier, a professor of ecology at Columbia University in NYC.

Now:

According to urban farming legend, Despommier challanged his students to implement a plan as an assignment.

The plan?

To produce food for all of Manhattan's millions of residents using only urban rooftop agriculture.

But there was a problem:

When the most optimistic design provided produce for only 2% of Manhattan's population, Prof. Despommier suggested the idea that would lead to the modern concept of vertical farming...

What he suggested:

Integrating urban agriculture with not just city rooftops, but also all of the floors of skyscraper style buildings. This concept could also be copied in independent vertical farming "towers".

So, what's the bottom line?

Despite the creation of the vertical farming concept multiple decades ago, the term has (oddly) only become popular on the internet (as evidenced by Google search volume) over the past 5-8 years (see image above).

How could that be?

The popularity surge could be attributed to the release of Despommier's book in 2010, "The Vertical Farm: Feeding the World in the 21st Century"

Today in 2020, vertical farming has taken the next stage in development. There are over 100 commercial vertical farming companies that have raised venture capital and are actually growing food that you have likely already purchased at the grocery store!

To learn more about these companies in detail, read our separate article, but for a short summary, see the section below.

The Vertical Farm by Dickson Despommier

Now...

We've covered so far:

1) the definition of vertical farming

2) the history of vertical farming

But you're also probably wondering:

What are the different types of vertical farms?

Or:

"What are the pro's and con's of vertical farming?"

Or:

"What are current examples of vertical farms?"

Or:

"How does vertical farming actually work (step-by-step)?"

Well you're in luck.

Why?

We are covering all of those parts next...

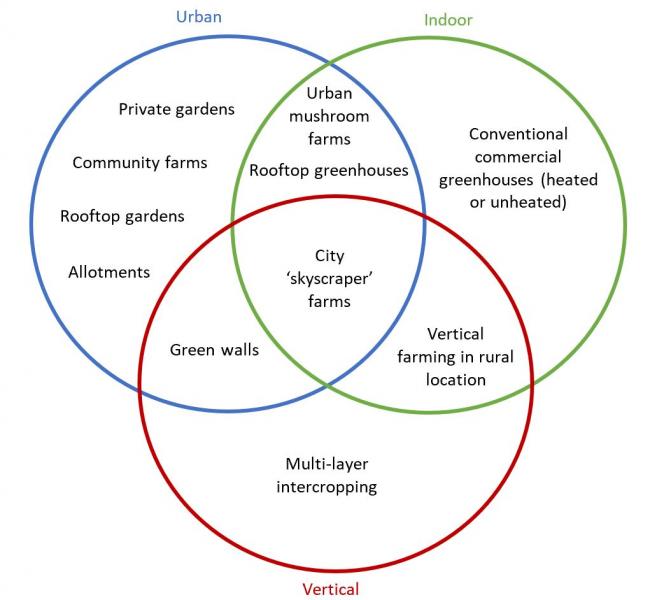

There are four main types of vertical farm design & architecture:

1) Mixed Use Skyscrapers & Despommier Skyscrapers

This concept of a vertical farm was one of the earlier concepts, and goes back over a decade (see this Scientific American article from over 10 years ago). The skyscraper "Despommier" vertical farm describes a vertical farming building which is intended primarily for food production, and all of the areas of the building have a function related to the vertical farm.

This design has still not yet widely become a reality in most areas of the world. The investment is high, and the unit economics do not currently allow for profitability in most scenarios.

2) Proprietary Modular Stacked Designs

This type of vertical farming architecture is the most commonly seen in commercial vertical farms today like Aerofarms, Bowery Farming, and other vertical farming companies.

The designs focus on modular repeatable components that are stacked on top of each other and often are housed in large industrial warehouses. These designs are proprietary and often include software to help manage optimum led lighting spectra, fertilizer input (hydroponic or aeroponic vertical farming) and airflow to help reduce mold growth.

3) Shipping Containers

Shipping containers have some similarities with the architecture discussed in section #2, except their are each confined within individual shipping containers.

Companies that are operating these types of designs include Freight Farms and Agricool.

Container farming companies are commercially operating today and therefore have a presence in the growing global vertical farming market.

4) Hobbyist / DIY Vertical Farming Designs

These systems, discussed further in the section below, #9 DIY Vertical Farming, are bottle, PVC, or wooden rack based home systems that allow for vertical farming at home for personal use.

Often these systems are DIY and will produce enough leafy greens or similar crop for a few individuals on a continuing basis.

These systems can be indoor, in a kitchen, or outdoor, in a garden environment.

For more information visit the section below!

Now, here's the deal:

Many experts have actually criticized Despommier's concept of vertical farming.

Why?

Here are common criticisms:

Cons:

- form over function: there are many critics of the Despommier vertical farming school of thought, for example, critic Stan Cox, a senior scientist at The Land Institute in Salina, Kansas and author of Any Way You Slice It: The Past, Present, and Future of Rationing has gone on record periodically since 2010 denouncing vertical farming (most recently in a February 2016 article in Treehugger.com titled "Vertical Farms: Wrong on So Many Levels").

Cox stated in a 2010 article titled "Vertical Farms aren't going to solve our food problems":

“Although the concept has provided opportunities for architecture students and others to create innovative, sometimes beautiful building designs, it holds little practical potential for providing food.”

- too expensive to operate from a financial perspective: from a unit-economics perspective, the profitability of vertical farming has been questioned (electricity usage, water usage, infrastructure cost). For this reason, community vertical farming has been supported over commercial vertical farming.

- too expensive to operate from a resource perspective (energy): a structure hundreds of feed tall would have issues with light pollution from the artificial lighting used in vertical farming and such a structure would require a lot of water to operate at peak performance (producing significant non-potable water waste).

But, here's there's also tons of supporting arguments:

Pros:

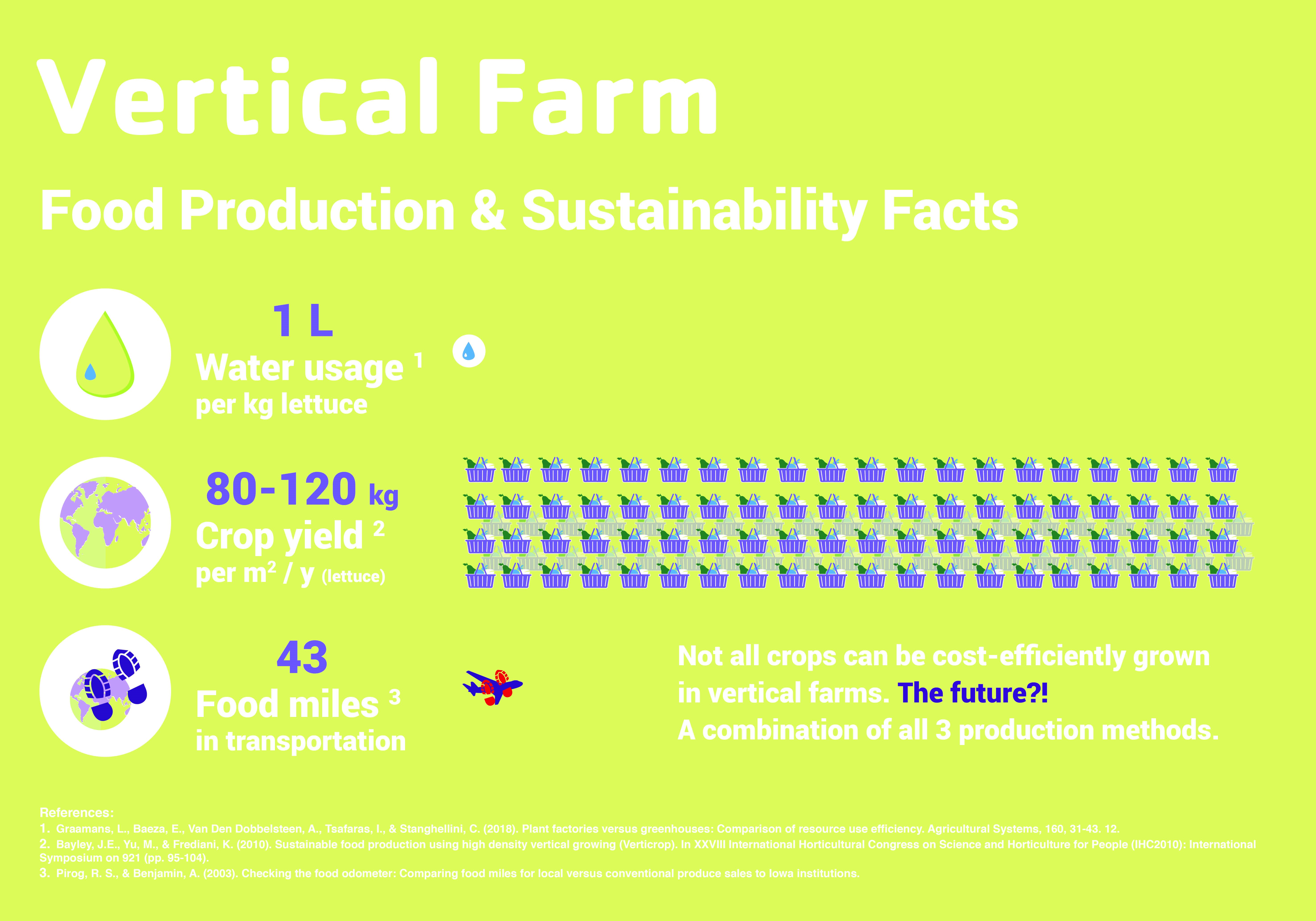

- reduction of "food miles": with massive local productio capability, and the urbanization of the world population, large scale vertical farming construction would reduce the average travel distance of food (some produce you buy at the store regularly travels thousands of miles from harvest to plate)

- reduction of stress on traditional farmland: overuse of traditional farmland is damaging to future production capability and expansion of farmland when current areas are not producing enough crop output leads to other negative effects like extinction of native species and environmental pollution.

Now:

We've covered the pros and cons.

So let's move on to the top reasons why vertical farms fail, plus current examples of vertical farms...

What are the specific reasons why vertical farms fail?

According to this post from Chris Michael, co-founder of Bright Agrotech, vertical farms fail for 3 key reasons.

1) Lack of Focus: It is common for vertical farms to try to both grow crops for sale as well as sell or license their actual growing technology. Said Michael,

"Farmers can either grow food or develop technology, but they shouldn’t do both"

2) Labor Costs

Although labor costs can be low on the unit scale, approximately $10/hr - $15/hr, the inefficiency of harvesting in many vertical farming systems make these costs add up more quickly than in a more conventional growing style.

Although automated harvesting options can potentially mitigate this cost in the future, it is still best practice to have a vertical growing design that makes it easy for labor to harvest.

Harvesting automation equipment has its own problems, such as:

1) upfront cost

2) skilled & expensive labor required to operate

According to Michael,

"Farmers should implement a growing system that reduces labor costs and does not require expensive automation technology to be economically viable."

3) Layout and Workflow Optimization

One warning for vertical farmers is to overlook the importance of efficiency in the entire growing process.

An efficiently designed vertical garden will have lower labor costs (see #2), less harvesting equipment, and will operate more like an "optimized system" than a form of art.

Michael concluded:

"When evaluating farm equipment options, look past production. Every system can grow crops, but not every system can optimize workflows and maximize labor efficiencies"

With these common pitfalls addressed, lets move onto some examples of vertical farms in action!

Read on to see video and text overviews of some of these farms (they're pretty cool!)

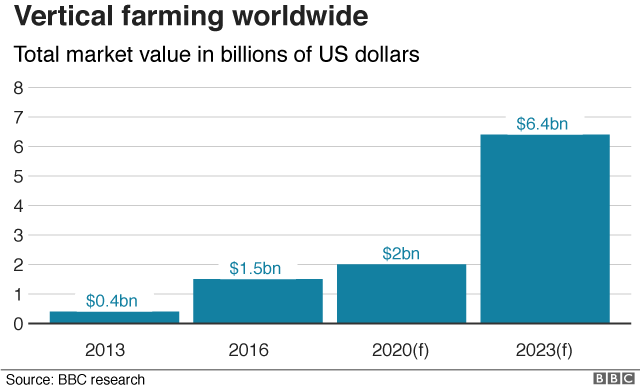

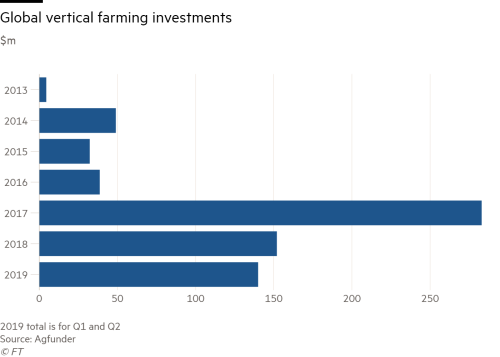

As seen above in data gathered from FT and AgFunder, in the past 3 years, investments in vertical farming in the private markets have increased by over 300% compared to the previous 3 year period.

Since much of this investment is so recent, vertical farming is still an an emerging market with limited public access to:

Although billions of dollars have been invested in vertical farming in recent years, most vertical farming enterprises are still private companies.

To get a complete breakdown of the top Vertical Farming Companies globally, their technology, history, and more, check out Vertical Farming Companies: The Advanced Report 2020 here!

For more simple and basic overviews, continue reading below!

Vertical farming startup Plenty has a well known list of investors, including Amazon's Jeff Bezos, but has recently caused headlines for temporarily closing some of their facilities.

Their new vertical farming proprietary architecture, Tigris, was unveiled in 2019. To learn more about Tigris, check out the video below!

Aerofarms has been "charting a course for a new standard of totally controlled agriculture" since 2004, so they have been researching vertical farming best practices for some time now.

Their proprietary vertical farming stacked designs reportedly use 95% less water and produce 390x higher yield per square foot annually than normal field grown techniques.

Credit: Hannah Hardaway / Vertical Harvest Jackson Hole

Here's a quick summary:

Vertical Harvest is 3 story hydroponic greenhouse in Jackson Hole, Wyoming, USA. It grows year-round and employs disabled members of local community.

But here's the crazy part:

The facility is only 4,500 sq feet, (418 square m), and utilizes a similar "carousel" design to the Plantogon controlled by timers to optimize light exposure.

The result?

Yield is approximately 100,000 pounds per year (45,000 kg approximately).

The growing medium used by Vertical Harvest is coconut husks (Plantagon uses peat moss).

What do they grow?

Leafy greens, herbs (basil), tomatoes, and microgreens.

Still craving more vertical harvest?

Check the video below.

Square Roots Vertical Farming is a container farming focused company based out of Brooklyn, New York in the US.

Over the past few years, they have announced partnerships with leading food distributors such as Gordon Food Service (GFS).

Although Square Roots gets a lot of media attention due to Kimbal Musk and the notoriety of his family, there have been alleged controversies linked to the Square Roots founder in wake of the COVID-19 pandemic.

Founded in 2016 by Kimbal Musk and co-founder Tobias Peggs, Square Roots has raised over $5.4M to date from investors and according to their LinkedIn page has between 51-200 employees.

Now:

Ater all this info, you may just be interested to know exactly how a vertical farm functions. ˆ

In other words:

"What are the actual components of a vertical farm?"

Well:

We cover a simple, step-by-step walk through of the components of a vertical farm below...

The bottom line:

There are four key areas to analyze the function of urban farming:

(1) physical layout

(2) lighting

(3) growing medium

(4) sustainability features

We can use the following example and break down the key characteristics and functions of a vertical farm:

First things first:

(1) The primary goal of vertical farming is to maximize the output efficiency per square meter / foot, resulting in a "stacked" tower like structure

Then:

(2) often a combination of grow lights and natural light will be used, technologies like rotating beds can increase lighting efficiency and natural light exposure

Now:

(3) growing medium can be hydroponic, aquaponic, or even aeroponic (no soil or other medium). Non soil mediums like coconut husks or peat moss are often used.

And finally:

(4) Sustainability features that offset the energy costs of the farm may include: rain water collection tanks, wind turbines, multipurpose spaces in the structure not used for cultivation.

If you are thinking about starting a vertical farm, you should focus on 4 aspects of your plan in order to be successful. These points are summarized from this article written by Amy Storey of Bright Agrotech.

There are 2 forms of vertical farming:

1. Growing on the normal horizontal plane and stacking beds vertically

2. Growing plants on a vertical plane (growing sideways)

Each of these growing styles in a vertical farm has different results for how space will be utilized.

Now, here's the key:

The key advantage for space utilization lies in vertical plane growing systems.

Why?

Vertical plane growing systems can have plants growing on both sides of the plane (think one plant growing sideways in each direction).

Additionally, harvesting is much less labor intensive with vertical growing plane systems in vertical farming, which we will discuss next (#2).

Growing in the vertical plane is usually a more efficient use of space than in the horizontal plane. source: Bright Agrotech Blog

The accessibility of your vertical farm is key to reducing labor costs. As discussed in detail above, the advantage once again falls with vertical growing planes that do not have stacked rows of plants.

Why?

Horizontally stacked rows of plants are not efficient to harvest, monitor, or otherwise tend to. Less efficient = more time = more labor cost.

For beginner vertical farmers, there's good news and bad news. Bad news first:

Bad News:

The idea among growers that higher volume leads to higher profits is common but false. Depending on the design of your vertical farm, costs increase at a faster rate with scale than crop production does.

Good News:

Focusing on unit profitability, not scale, is doable even for a beginning grower.

How does one focus on profitability? Focusing on efficiency (#1), labor cost management (#2), and investing in environment and plant health (#4 below), is a great start toward profitable vertical farming.

A couple key aspects of your vertical farm should be considered with regard to environment and plant health:

1) How optimized is the system for heat dissipation? Grow lights will generate heat, regardless of what type, and optimizing airflow will be helpful.

2) How well does the system distribute excess moisture?

3) How well do gases like CO2 circulate?

All of the factors above are optimized generally speaking from employing vertical plane growth over stacked horizontal plane growth.

For further details, check out this article "How Vertical Farming Works To Maximize Crop Output"

Although you may not be able to construct multi-million dollar vertical farm racking system with led lights at your home, there are ways to do vertical farming at home, especially vertically farming outdoors.

In this section we will cover your best options.

A 2017 article from Soilless.org cites 2 primary solutions for vertical farming at home and DIY vertical farming.

1. Vertical Farming Bottle Tower System

This is a system designed by Willem Van Cotthem, Professor of Plant Morphology at the University of Ghent in Belgium.

2) Tower Farm Wall

A farmwall design is a lot more sturdy than example #1 above, however does require more construction time. This system includes:

- a base (wood)

- a frame (wood)

- rolling wheels (plastic)

- screws (steel)

- drill

- measuring kit

For more information on farmwall construction, check out our in-depth guide on vertical farming (the final chapter)!

Most people want to know when it comes to vertical farming:

How profitable is vertical farming?

How much food does a vertical farm produce?

Sourced via Sarah Hughes via Agrylist (2017)

According to 2017 data above originally from Agrylist, nearly all vertical farming crops grown commercially sometimes are not grown at a profit.

Specifically, herbs and leafy greens are more frequently not profitable in a vertical farming system vs profitable.

According to this data set, flowers, microgreens, and tomatoes are more likely to be grown at a profit in a vertical farming system.

For more information on this specific study, see the full report here.

On the macro-scale, the investment required to start a vertical farm is much higher vs traditional farming:

While leading vertical farm company Aerofarms claims it can produce 390x more food per acre with 95% less water, other groups have different opinions. The Koch Institute, for example, critcized the economics of vertical farming in early 2020, saying that while 2 acres of vertical farm production costs $39 million to start up, an acre of farmland in Iowa costs about $8,000 to maintain.

On the macro-scale, the investment required to start a vertical farm is much higher vs traditional farming.

This 2019 article from Duke University points out that while some crops can have up to 540x higher yield per unit area in a vertical farming system, and that the speed to grow a crop that is ready to harvest can be shortened by as much as 50% (60 days to 40 days), the upfront cost of set up is often times 100+ million dollars.

For even more information on the unit economics, check out Vertical Farming: The Advanced Guide!

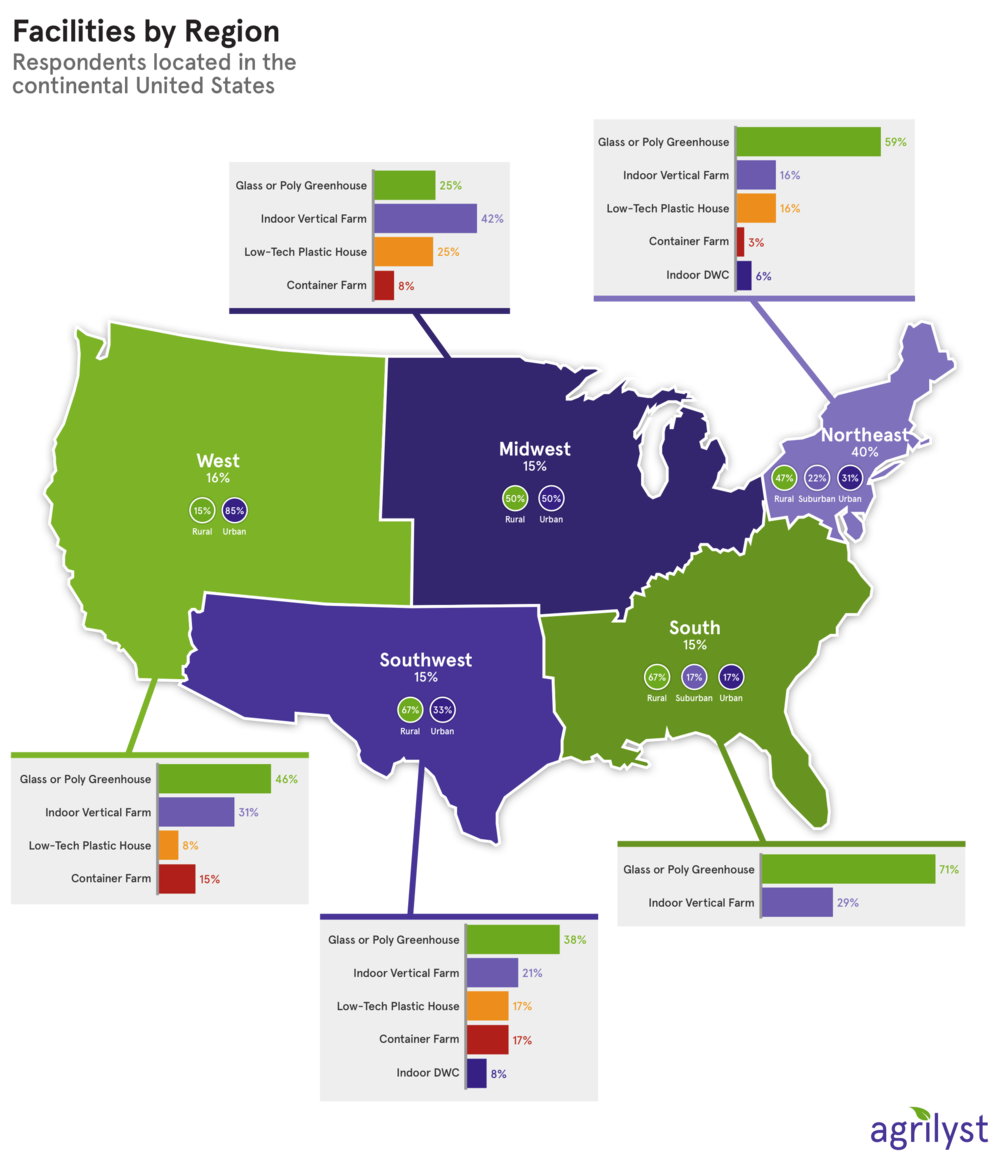

The US is one of the largest vertical farming industries in 2020. Below there are breakdowns of vertical farming in each of the major US cities.

Vertical Farming New York City

New York is a hotspot for vertical farming activity, with notable companies such as farm.one and Bowery Farming. This recent article from the NY Daily News discusses in further depth the industry in New York.

Vertical Farming Philadelphia

Philadelphia is also a growing hub for agriculture infrastructure. More details can be found in this November 2019 GreenBiz article, The Vertical Farming Industry is Growing Deeper Roots.

Vertical Farming Boston

Boston is another east coast city in the US that is progressive when it comes to Vertical Farming. Two notable companies include Freight Farms, makers of the "Greenery" vertical production system, and FreshBox Farms.

Vertical Farming New Jersey

New Jersey is most closely linked with Vertical Farming due to due Aerofarms and their facility there. See the video below to learn more!

Vertical Farming Seattle

Seattle has made the most news recently in the Vertical Farming space for a project that did not happen versus a project that did happen. Vertical Farming startup Plenty postponed plans to open a facility near Seattle in late 2019.

Operational vertical farms in Seattle include FarmBox Greens, a division of Charlie's Produce.

Vertical Farming Chicago

Although Chicago is the 3rd largest city in the US and arguably the countires most important supply chain hub, vertical farming has yet to take root in this midwestern US city. This 2019 article in the Chicago Tribune attempts to detail why.

Vertical Farming Singapore

Singapore has been a center of Vertical Farming Innovation over the last decade. To learn more about how and why, see the video below!

Vertical Farming Japan

Japan has always had a reputation as an innovative country when it comes to technology. Pair this fact with Japan's development as a country and economy and you have the right recipe for vertical farming innovation.

Below is a comprehensive run down on the state of Vertical Farming in Japan.

Vertical Farming India

India, which most experts predict to have the largest population and global market for food in 2050, has likewise been innovating when it comes to vertical farming technology.

The clip below features 365dfarms, India's first "movable hydroponic farm".

One thing is clear:

Vertical farming is advancing across the world.

So what are the key benefits of vertical farming that are driving this advancement ?

Read the section below to learn more!

Vertical Farming Advantages Include At Least the Following:

1) Increased Yields: Depending on the source, yield per square acre can increase between 10x and 500x!

2) Protection from weather-related events: As an indoor production system, weather events that have drastically affected agriculture for thousands of years are not a major factor reducing production capacity.

3) Shorter distance to market: Most vertical farms are strategically located near end markets, for example, many vertical farms on the US east coast service the 100+ million residents that reside on the US east coast.

4) Faster Growth Cycles: With vertical farming, growth cycles can be reduced by over 50%.

5) Less Water Usage: According to leading vertical farms, water usage is reduced by 95-99% compared to traditional agricultural production.

6) More Space Efficient: Most vertical farms are 1-2 acres in size, and produce as much product as 100 or even 1000 acre farms.

7) Less Food Waste: With local market production and more optimized growing practices, vertical farms have the potential to have less wasteful supply chains.

Hydroponics is a form of agriculture which utilizes water and nutrient solution instead of soil as a growing medium.

As seen below, the hydroponics market is steadily growing, and this growth is driven in part by the growth of the vertical farming industry.

Many vertical farms use hydroponic technology in their designs. One key reason is that soil is too heavy to use as a growing medium in a vertical farm with many levels of grow-racks.

To learn more about hydroponics and how it works, check out this article!

Incorporating some suggestions from our friends at Vertical Urban Farming Project combined with a shameless self plug, here are our top 3 picks:

1) The Vertical Farm: Feeding the World in the 21st Century (Dickson Despommier)

2) Vertical Farming: The Advanced Guide (Urban Vine)

3) The Urban Farmer: Growing Food For Profit (Curtis Stone)

Helpful Lists and Resources for Vertical Farming Jobs:

Vertical Farming Jobs (Glassdoor)

Ponic Jobs

Angel List

Plenty Jobs

For a full list of vertical farming companies, follow this link.

Vertical ocean farming is a distant cousin of traditional vertical farming which uses submerged growth structures to grow plants such as seaweed and kelp underwater.

Although there are not many similarities with "land" vertical farming, there are some similarities, for example, the vertical plane of plant growth.

To learn more, check out the Ted talk on vertical ocean farming below!

The major cost centers of a vertical farm boil down to a few items.

Most notably:

(1) lighting systems (and the energy needed) and

(2) real estate

(3) racks, tubing, and other elements of the "vertical farming structure"

are significant costs for vertical farmers.

Below are expansions of each area above:

(1) As far as lighting systems go, horticultural grow light manufacturers extend services for vertical farm planning in addition to selling grow lights, and therefore these companies can be advisors for purchasing vertical farm equipment and systems.

To learn more about the different grow light suppliers, be sure to check out Indoor Grow Light Companies: The Advanced Report 2020

(2) Selecting a site for your vertical farm involves at least 2 important considerations.

a) Zoning laws in your area of choice may determine whether or not a commercial vertical farm is even viable on the property you are considering

b) Tax breaks and and grants may provide a significant savings for you when selecting property for a vertical farm. For example, Aerofarms 2017 New Jersey facility reportedly received $6.5 million in tax credits in addition to a $2.2 million grant for building its vertical farm in the state of New Jersey.

Keep in mind many of tax and grant opportunities are also related to the sustainable nature of a vertical farming facility. For more info on grants for urban farms, check out our expanded post here!

(3) For off the shelf, lower value items such as racks, tubing, PVC, and other similar items, hydroponic equipment suppliers or even online vendors can potentially supply vertical farming equipment.

Potential Helpful Links:

https://www.alibaba.com/showroom/vertical-farm-equipment.html

https://amzn.to/3ezml30

As vertical farming has continued to develop globally, supporting organizations have formed to help continue to foster the growh of the industry.

One of the leading organizations doing this work is the AVF, founded in Munich, Germany in 2013.

The Association For Vertical Farming (AVF) is an internationally active nonprofit organization fostering the sustainable growth of the vertical farming industry through education and collaboration. The AVF focusses on advancing Urban and Vertical Farming technologies, designs and businesses.

To learn more, visit https://vertical-farming.net/

Aquaponics refers to the cultivation of fish in conjunction with hydroponic farming. At this time, there is not a significant amount of commercial vertical farms using aquaponic growing techniques, with most companies utilizing more simple hydroponic or aeroponic techniques.

To learn more about aquaponics, visit https://www.urbanvine.co/blog/3-basic-types-of-soil-less-growing-methods-beginner-urban-growers-should-know-about

Aeroponic growing, as seen in the diagram below, refers to a soilless growing system in which plant roots are misted with spray nozzles as opposed to being submerged in a the hydroponic nutrient solution.

Proponents of aeroponics believe it can lead to benefits such as increased water savings and utilization, whereas some experts view aeroponics as having significant challenges compared to hydroponics, including:

1) need to be more precise with nutrient dosing

2) spray nozzles can become clogged, degrade, and then are inaccurate

3) Dependent on pumps and timers for misting cycles, if there is a failure, plants will likely die

For more of a discussion on aeroponics vs hydroponics, visit the following Quora thread: https://www.quora.com/What-are-the-disadvantages-of-aeroponics

Because of the challenges stated above, hydroponics are more commonly used in vertical farms compared to aeroponics.

Now, to learn more about the role of LED grow lights in vertical farms, keep on reading below!

According to former Chipotle CMO's Mark Crumpacker's 2018 medium post "4 things you need to know about LEDs and vertical farming", LED grow lights have driven a lot of the viability of vertical farming over the past decade. To summarize Mark's in-depth post:

1) Modern LED's are optimally suited for vertical farming. By some estimates the cost of LED grow lights dropped by 90% from 2010 to 2014, enabling many vertical farming innovations.

2) LED's allow targeted wavelengths which allow higher yield for vertical farms.

3) LED's are still a complicated topic when it comes to vertical farming. There are many choices and customization options for growers, which is one reason why many current growing systems are proprietary.

4) LEDs do still have some disadvantages. One primary disadvantage is cost. Although LED's have dropped in cost significantly there are still economic barriers compared with metal halide and other types of grow lights.

Up next, we will discuss the relation of greenhouses and vertical farming!

Although Vertical Farms and Greenhouse farms do have some differences, they share some characteristics.

For example, many greenhouses will still use grow lights, and as seen in the infographic above, the types of crops that greenhouses grow tend have some similarities with vertical farms (vegetables such as leafy greens).

However, there are some key differences between vertical farms and greenhouses:

1) Vertical farms use many stacked layers of vegetables, whereas greenhouses typically only have one "plane" or layer of production.

2) The crops grown in a greenhouse can vary slightly from pure vertical farms. For example, it is not common currently for vertical farms to grow crops like eggplants and peppers whereas these crops are more frequently grown by commercial greenhouses.

For more information on commercial greenhouse growers in 2020, see our advanced report Commercial Greenhouse Growers: The Advanced Report 2020.

Next up, we will cover vertical farming diagrams and the specific components that most vertical farms feature.

Read on to learn more!

Listed below are the top 10 PDF format studies on Vertical Farming according to Google Scholar:

1) Vertical Farming: Skyscraper Sustainability (2015)

2) Plant Factory, an Indoor System for Efficient Food Production (2019)

3) Up, Up, and Away! The Economics of Vertical Farming (2014)

4) Vertical Farming: Social Work and Urban Agriculture in an Age of Food Crisis (2013)

5) Future Food Production Systems: Vertical Farming and Controlled Environment Agriculture (2017)

6) Vertical Farming Increases Lettuce Yield Per Unit Area Compared to Traditional Farming (2016)

7) Opportunities and Challenges in Sustainability Related To Vertical Farming (2018)

8) A review of Vertical Farming: Building Integrated Agriculture in Cities (2017)

9) Recent Trends in Vertical Farming and Organic Farming (2015)

10) Why Vertical Farming Doesn't Stack Up (2010)

The research above is just a small piece of the research conducted on Vertical Farming over the course of the past decade. The links above allow for PDF access and ease of viewing.

To learn even more about vertical farming, check out Vertical Farming: The Advanced Guide, today!

Photo by Conscious Design on Unsplash

According to this 2017 article, the top crops to grow using vertical farming are:

Vertical Farming Cannabis

As of 2020, Cannabis is not frequently grown on vertical farms. As this market is rapidly changing and legal guidelines are develop and evolve, this current state can quickly change.

Generally speaking, cannabis is not a focus area for urbanvine.co, to get more information on this topic, visit this August 2019 article "Is Vertical Growing the Future of Cannabis?"

You now know the basic background information relating to vertical farming.

Why is that important?

Here's your real takeaway (if you forget everything else):

Vertical farming is growing at an incredibly fast pace (the market is pretty much exploding, and there's ample proof).

Getting to know the background of vertical farming, is just the start of your urban farming journey.

If you liked this article....

Check out our other aritcles and subscribe below!

Short on time?

This interview details Libra Design, an indoor farming technology company based in the United States. The interview is with Travis Williams, Co-Founder & CEO of Libra Design. To learn more about Libra Design and other indoor farming companies, click on this link!

View Full Interview

This interview details BioSafe Systems, a company based in the United States. The interview is with Eric Smith, National Sales Manager (Horticulture Division) at BioSafe Systems. To learn more about BioSafe Systems and other indoor farming companies, click on this link!

View Full Interview

This interview details McNabb MicroFarm, an indoor farming company based in the United States. The interview is with Lauren McNabb, Head of Marketing at McNabb MicroFarm. To learn more about McNabb MicroFarm and other indoor farming companies, click on this link!

View Full Interview

This interview details Griffin, an indoor farming company based in the United States. The interview is with Tami Van Gaal, Director of Vendor Relations at Griffin. To learn more about Griffin and other indoor farming companies, click on this link!

View Full Interview

This interview details Virgo Global Inc., a company based in Canada. The interview is with Guillaume Paquet, Director R&D at Virgo Global Inc. To learn more about Virgo Global Inc. and other indoor farming companies, click on this link!

View Full Interview

This interview details Corridor Farmers, an indoor farming company based in Singapore. The interview is with Roc Koh, CEO of Corridor Farmers. To learn more about Corridor Farmers and other indoor farming companies, click on this link!

View Full Interview.jpg)

This interview details Affinor Growers, an indoor farming technology company based in Canada. The interview is with Nick Brusatore, CEO of Affinor Growers. To learn more about Affinor Growers and other indoor farming companies, click on this link!

View Full Interview.jpg)

This interview details Ina Plastics, a company based in Greece. The interview is with Jacob Tsonakis, Founder and CEO of Ina Plastics. To learn more about Ina Plastics and other indoor farming companies, click on this link!

View Full Interview

This interview details Funga Farm, an indoor farming company based in Denmark. The interview is with Thomas Kyle Cometta, Owner of Funga Farm. To learn more about Funga Farm and other indoor farming companies, click on this link!

View Full Interview

This interview details Savills, a company based in the UK. The interview is with Joe Lloyd, analyst Savills rural research. To learn more about Savills and other indoor farming companies, click on this link!

View Full Interview